Our Ghanian Client Natural Gas Pipeline Network is a 320 km natural gas pipeline network in southwestern Ghana which interconnects Our Ghanian Client power generation plants to the Ghana National Gas Company’s Prestea Regulating and Metering Station (PRMS). The network is being rolled out over three phases with the 80 km Prestea Regulating and Metering Station (PRMS) segment currently operating.

Contents

1 Location

2 Project details

3 Background

3.1 Expansion: Kumasi pipeline project

4 Articles and resources

4.1 References

Location

The pipeline runs from the PRMS to the Tarkwa and Damang plants. The second phase is proposed to run from the PRMS to the Chirano plant and a proposed bauxite refinery in and around Nyinahin. A third phase will interconnect phase one and two to the Edikan and Wassa power plants.

Project details

Capacity:

Length: 350 km

Diameter:

Status: 80km operating, 155 km in construction and 85 km proposed .

Start year: 2019

Cost:

Financing:

Background

Our Ghanian Client has developed a 320 km natural gas pipeline network in southwestern Ghana to interconnect its power generation plants to the Ghana National Gas Company’s Prestea Regulating and Metering Station (PRMS). Construction of the pipeline network is is being rolled in three phases with the first phase currently active. In May 2019, it was reported that Our Ghanian Client commissioned an 80km natural gas pipeline that interconnects the PRMS to the Tarkwa and Damang plants. Construction of the 155km natural gas pipeline to interconnect the PRMS to the Chirano plant and a proposed bauxite refinery in and around Nyinahin has begun with plans to further construct an 85km natural gas pipeline which will interconnect the 80km and 155km natural gas pipelines to the Edikan and Wassa power plants[1]. The pipeline is connected to the Atuabo–Aboadz gas pipeline at Ghana National Gas Company’s Prestea Regulating and Metering Station (PRMS).

Expansion: Kumasi pipeline project

In July 2022, it was reported that Our Ghanian Client had secured $425 million to finance a 100km natural gas pipeline to Kumasi, Ghana’s second largest city, a 200mmscfd gas conditioning plant at Prestea and a Natural Gas Liquid storage terminal at Takoradi Port . Completion of the new pipeline was announced in June 2023. The new pipeline will ensure availability of cheaper and readily accessible piped natural gas in Kumasi and the central belt of Ghana and allow industries to switch from imported diesel and heavy fuel oil (HFO) to indigenous natural gas.

The construction of the natural gas pipeline to Kumasi and the gas processing plant in Prestea will have significant economic and environmental benefits not only for our client but also for Ghana and the West African sub-region. The project will support our client’s diversification from power to the gas midstream sector and mark a significant milestone in its decarbonization strategy to achieve net zero carbon by 2035 while contributing significantly to Ghana’s national climate change targets on emission reduction.

Our scope of works in this project main comprised of the followings:

1. Natural Gas Conditioning and processing Plant Equipment platform structural steelworks;

2.LNG tanks

3. LNG tank foundation formworks (Prefabricated steel plate formworks);

4. Various site workshops(maintenance, chemicals, fabrication,plateworks,storage,warehouses) with overhead cranes;

5. kilometers of pipe racks and LNG equipment processing platforms;

Project execution period: May,2023 to April 2024.

The followings are the progress photos of the production and constructions of this projects:

General: Site general status photos(in progress):

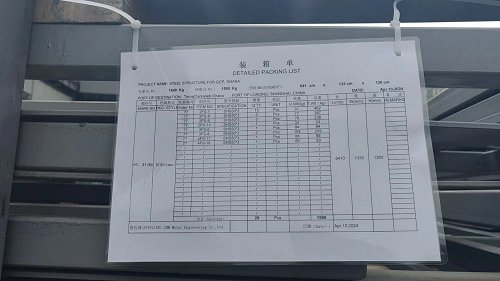

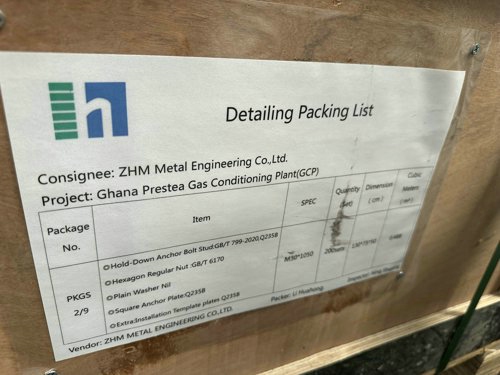

Shipping Mark and Packing List Break Bulk Steel Structure Truck Loading in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

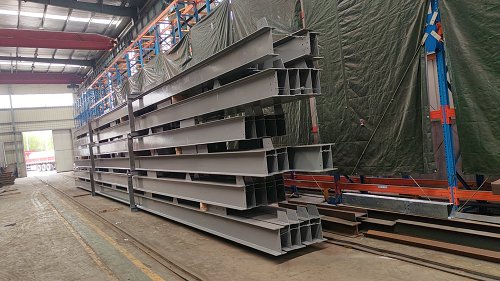

21meters over-long steelworks Break Bulk Steel Structure Truck Loading in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

21meters over-long steelworks Break Bulk Steel Structure Truck Loading in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

Checkered plate steelworks Break Bulk Steel Structure Truck Loading in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

21meters over-long steelworks Break Bulk Steel Structure Truck Loading in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

21meters over-long steelworks Break Bulk Steel Structure Truck Loading in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

21meters over-long steelworks Break Bulk Steel Structure Truck Loading in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

Break Bulk Steel Structure Truck Loading in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

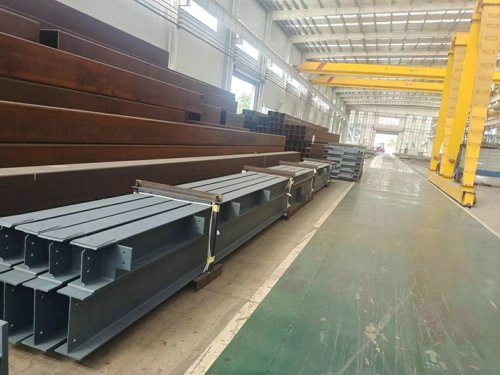

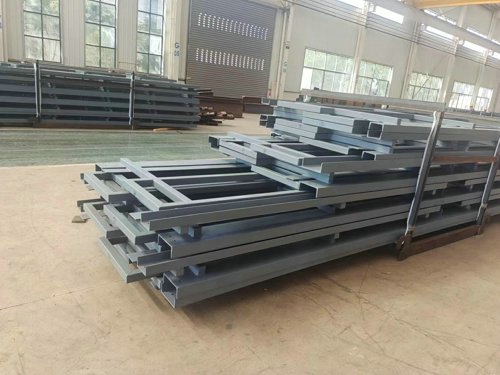

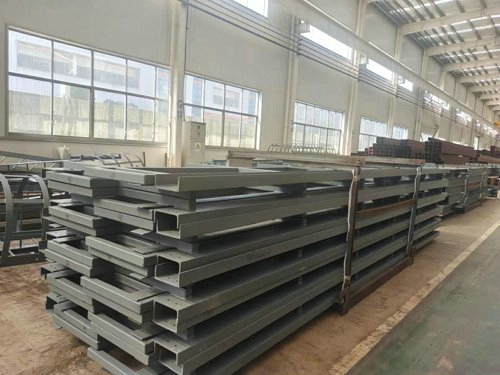

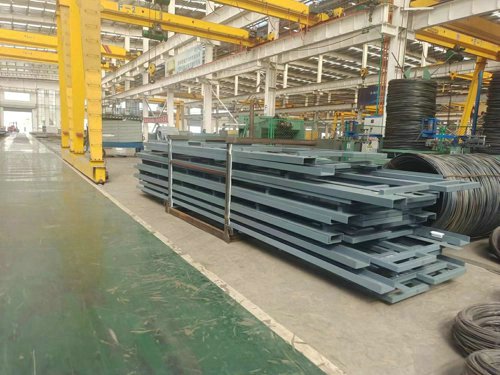

Break Bulk Steel Structure Stack Piling in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

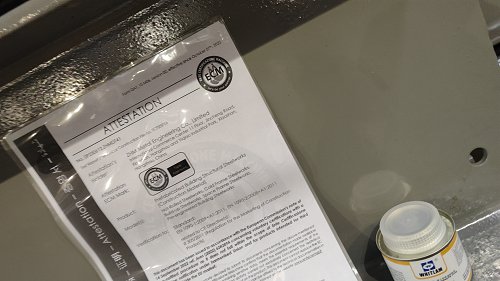

CE certificate For Manufacturing of Steel Structure Stack Piling in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

Break Bulk Steel Structure Stack Piling in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

Break Bulk Steel Structure Stack Piling in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

Break Bulk Steel Structure Stack Piling in Factory for Pipe Racks and Equipment Platform Steel Structure for Ghana Natural Gas Pipeline Network

The followings are the progress photos of the production and constructions of this projects:

General: Site general status photos(in progress):

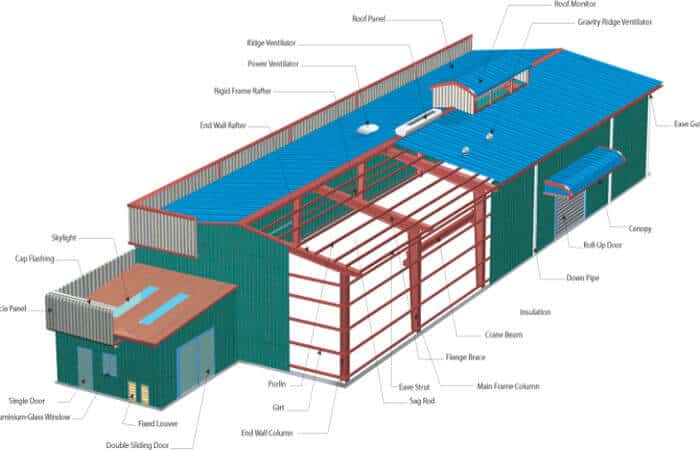

Various site workshops(maintenance, chemicals, fabrication,plateworks,storage,warehouses) with overhead cranes;

Pipe Rack and equipment platform sites.

General View

Various site workshops(maintenance, chemicals, fabrication,plateworks,storage,warehouses) with overhead cranes;

1. Natural Gas Conditioning and processing Plant Equipment platform structural steelworks;

2.LNG tanks

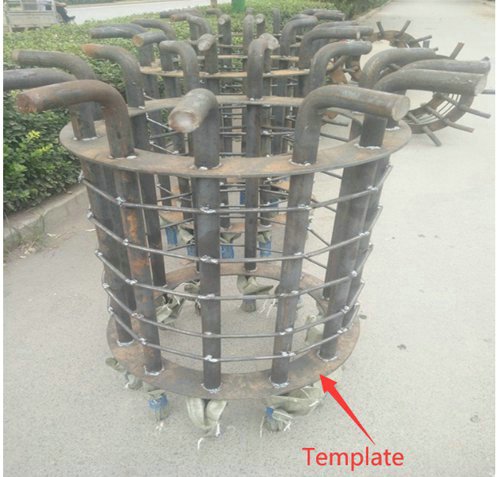

3. LNG tank foundation formworks (Prefabricated steel plate formworks);

4. Various site workshops(maintenance, chemicals, fabrication,plateworks,storage,warehouses) with overhead cranes;

5. kilometers of pipe racks and LNG equipment processing platforms;

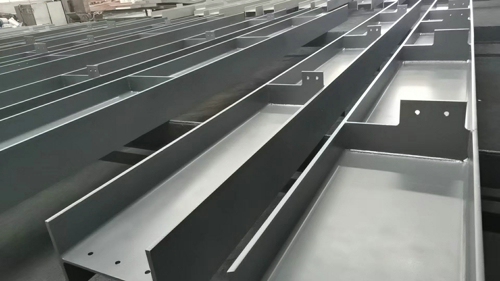

Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

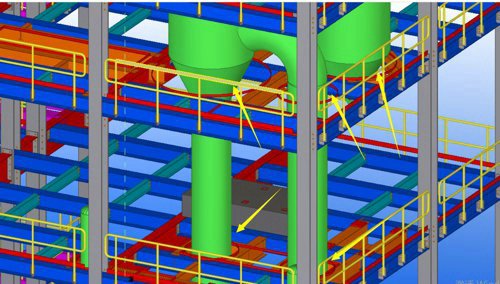

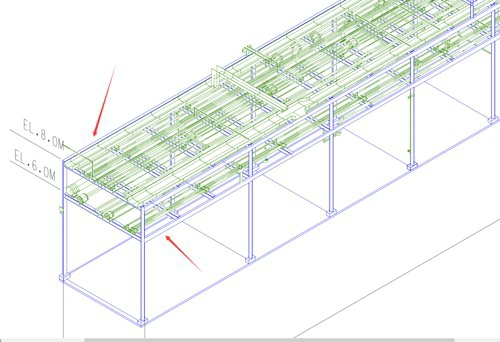

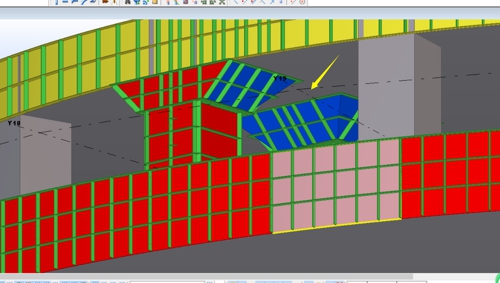

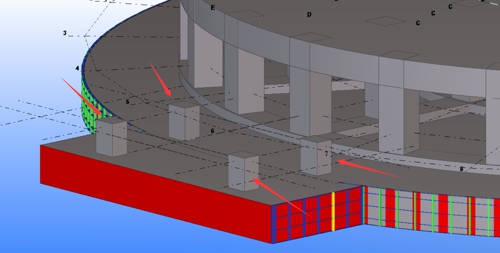

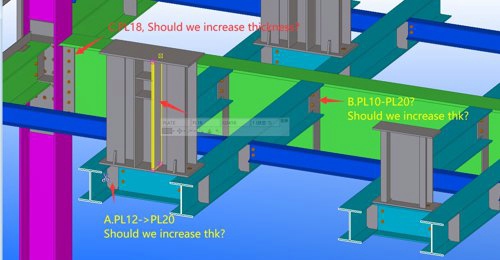

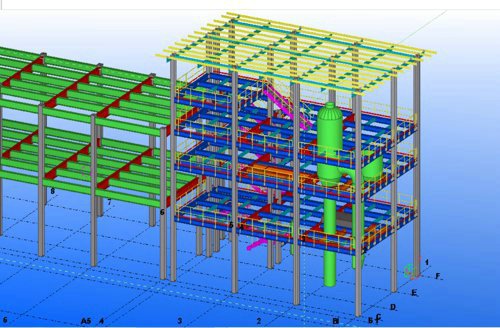

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks: Design 3D BIM model

Above picture is: Site admin office and temporary workshop/storage.

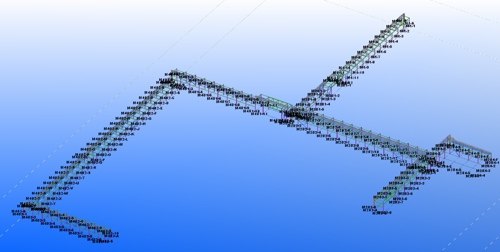

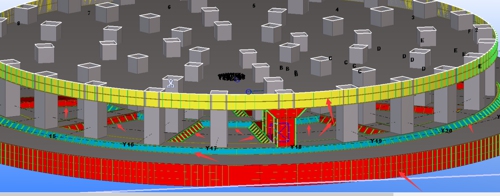

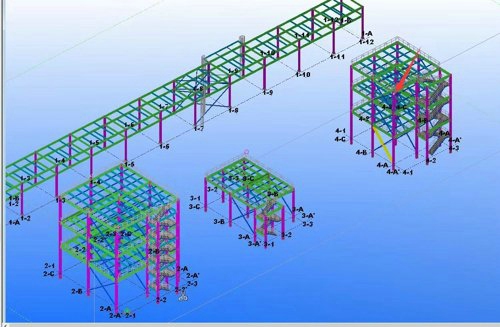

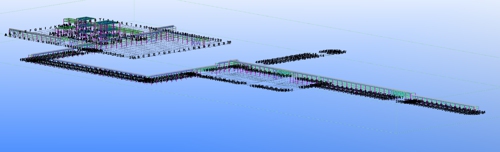

Above picture is: Natural Gas Pipe Rack structural steelworks: Design 3D BIM model

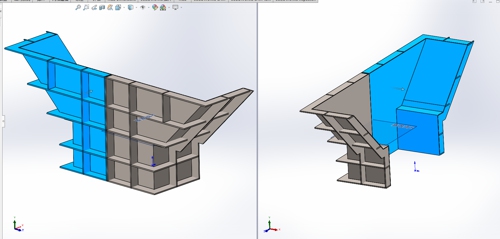

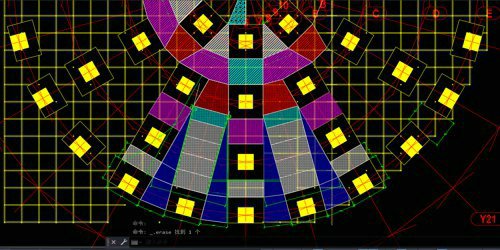

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Design 3D BIM model

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in Open top container loading work

Above picture is: Natural Gas LNG tank equipment platform packing at port for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks: Fabrication work

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks : open top container loading work.

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: site installation.

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks: Stack Anchor bolts and templates plates

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in Open top container loading work

Above picture is: Site admin office and storage center.

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: site construction

Above picture is: Natural Gas Pipe Rack structural steelworks: Design 3D BIM model

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks : open top container loading work.

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Scalfolding work construction.

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks : Painting in progress

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Design 3D BIM model

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Design 3D BIM model

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Design 3D BIM model

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Design 3D BIM model

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks: 3D model BIM communication.

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks: 3D model BIM communication.

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Design 3D BIM model

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Construction in progress

Above picture is: Natural Gas Conditioning and processing Plant Equipment platform structural steelworks in break bulk packing condition ready for shipment

Above picture is: Natural Gas Pipe Rack structural steelworks: Design 3D BIM model

Above picture is: Prefabricated LNG tank foundation formwork structural steelworks: Factory pre-assembly

ZHM LNG Projects Design and Service Reference List

1. 300,000Nm³/d Peakshaving LNG Plant Pre-Treatment Unit Revamping 2018. SoW: Re-design of the unit, Procurement of Catalyst,Site Installation for pipings and Adsorbents, Startup and O&M Service and Training, Lanzhou, Guansu Prov., China. Status: Plant Startup successfully and Plant Under full-load operating 2018

2. 0.1MMTPA LNG Plant BOG and MR Unit Revamping 2018. SoW: Re-design of the unit, Sepc for procurement,Site Installation Supervision, Startup and O&M Service and Training,Jingbian, Shaanxi Prov., China.Status: Plant Startup successfully and Plant Under full-load operating

3. 500,000Nm³/d LNG Plant Flare System Emergency Accident Handling and Flare System Repairing 2019. SoW: Emergency Handling, Stress Analysis for Cold Flare Piping System, System Re-design,Sepc for procurement,Site Installation Supervision, Startup Service and Training,Jingbian, Shaanxi Prov., China. Status: Plant Startup successfully and Plant Under full-load operating

PMC for An Inner Mongolia 0.4MMTPA LNG Plant ,Inner Mongolia, China. Status: Plant Startup successfully and O&M Service Ongoing. 2019-2020

4. Process Design Verification and HAZOP, QRA Study for a Base-Load LNG Plant Overseas. Proejct Status: Ongoing 2020

5. De-Bottleneck and Process Optimization Study for A 0.2MMTPA LNG Plant in Ningxia, P.R.China. Status: Plant Bottleneck identified and removed and Plant Startup successfully and Under full-load operating. 2019

6. 300,000Nm³/d small-scale LNG Plant Process Optimization. SoW: Optimization of the current process design, Procurement of Catalyst,Site Installation, Re-startup and O&M Service and Training, Lanzhou, Guansu Prov., China. Status: Plant Startup successfully and Plant Under full-load operating 2019-2020

7. PDP Design of a LNG-Fuel Ship Fuel System. SoW: Aspen Hysys Steady and Dynamic Simulation (16 cases) , HEX Design and Selection, PDP Deliverables of the LNG fuel system for a big bulk cargo ship, CSSC, China. Status: Ongoing 2019-2020.

8. Rotating Equipment Maintenance and Process Optimization for A 1MMNM³/D LNG Plant in a NW Prov., P.R.China. Status: Ongoing 2020. Shop Test Accomplished Successfully

20,000TPA LSTK Project of a Coal Gas Separation and Liquefaction, Shaanxi Prov., P.R.China. Ongoing