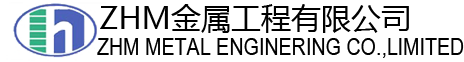

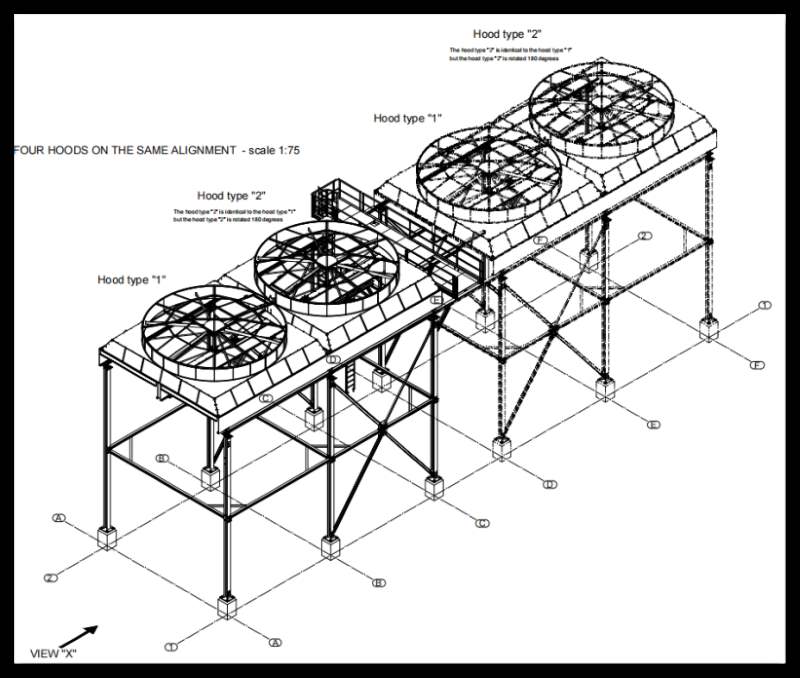

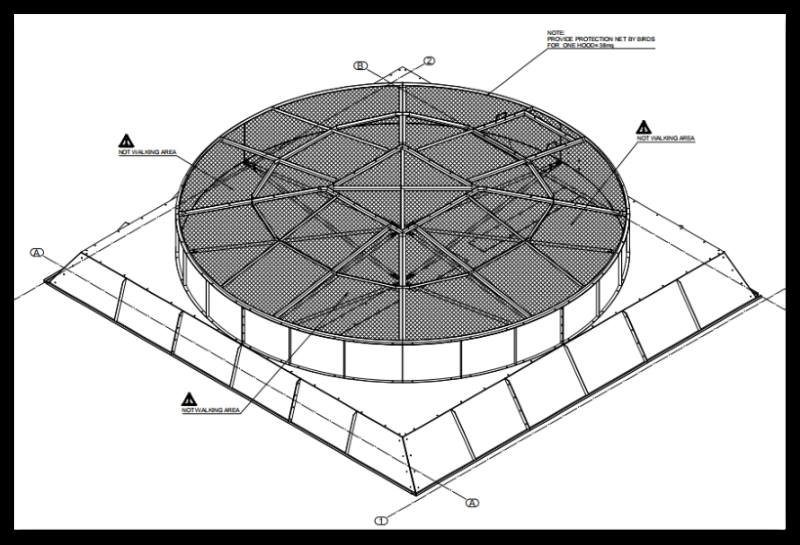

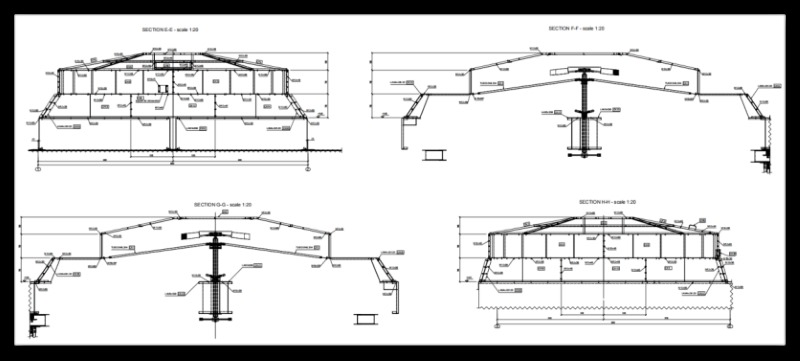

Upper Steel Structures (ACC, Hood Type Building) with Bird Protection Net at GEX 3300-Emir-33MW Geothermal Power Plant, Turkey

1. Scope

2. Key Components

Channels: UPE/UPN profiles for primary support beams.

Angles: L-shaped sections for bracing and secondary supports.

Plates: Connection plates, gussets, and base plates (thickness as per load calculations).

Bird Protection Net:

Mesh material (e.g., stainless steel or UV-stabilized polypropylene, if unspecified).

Attached to the steel framework via galvanized clamps or hooks.

3. Material Specifications

Hot-Dip Galvanizing: Coating thickness ≥ 85 µm (ISO 1461 compliance).

Post-fabrication galvanizing to ensure full coverage.

Fasteners:

Bolts: Grade 8.8 (M12–M24), hot-dip galvanized.

Nuts/Washers: Grade 8 galvanized, matching bolt specs.

4. Design Considerations

Wind loads (per Turkish Building Code/EN 1991-1-4).

Seismic loads (Turkey Zone 2/3 compliance).

Dead load of structure + netting.

Corrosion Resistance:

Critical for geothermal environments (high humidity/H₂S exposure).

Double-check galvanizing quality at weld-free zones (if any).

Modularity:

Pre-drilled holes for bolted assembly; tolerance ±2mm.

Allow for future maintenance access.

5. Fabrication & Installation

Cut, drill, and label all steel components.

Galvanize after fabrication to avoid coating damage.

Pre-assemble modules for quality checks.

Installation:

Erect primary steel structure using cranes.

Bolt connections tightened to 70% of proof load (per EN 14399).

Attach netting with tensioning systems to prevent sagging.

6. Compliance & Testing

ISO 1461 (galvanizing), EN 1090 (steel fabrication), EN 1993 (design).

Turkish seismic codes (TEC 2018).

Quality Control:

Mill certificates for steel.

Coating thickness tests (magnetic gauge).

Bolt torque testing (30% random checks).

7. Challenges & Solutions

Oversize bolt holes by 2mm to accommodate zinc buildup.

Net Durability:

Specify nets with anti-corrosion coatings if non-stainless.

8. Deliverables

Galvanizing inspection reports.

Bolt/nut certification (Grade 8.8).

We ZHM, specialize in manufacturing and erecting air-cooled condensers according to customers’ specifications.

- Substructures

- Steel structures

- Steam ducts

- Heat exchangers

- Propulsion fans, axial blowers

- Ribbed tubing

- Compensators and valves

- Accessories such as condensate tanks and drainage tanks

- Air removal equipment

- Tube piping with pumps and associated fittings

- Instrumentation

The prefabricated parts are delivered to various construction sites across the region where they are professionally erected.

Why ZHM Huawu Metal Upper Hood Steel Structures For ACC Air-Cooled Condenser Buildings ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Upper Hood Steel Structures For ACC Air-Cooled Condenser Buildings ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com