25 days to complete the installation of 6800 tons of steel structure, we did this

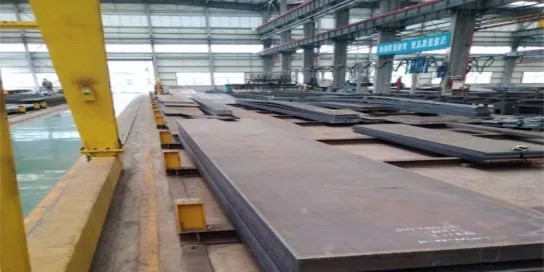

The Qianhai International Conference Center project is a comprehensive building integrating conference center, exhibition functions, and international exchange activities. The total construction area of the project is about 40,500 square meters, the roof height is 31.5 meters, and the total steel consumption is about 6,800 tons. Specific work includes detailing, fabricating, painting and shipping.

The biggest feature of the project is "designing, deepening and construction at the same time". And in the construction process, it has experienced huge changes - the amount of steel used has increased from 3,300 tons to 6,800 tons now, and the construction period has been reduced from 45 days to 25 days.

In the face of doubling the amount of steel used and shortening the construction period by nearly half, the construction team achieved a remarkable achievement of completing the installation of more than 2,000 tons of steel structures in seven days, ensuring that the project was delivered on time. How did we do it?

All parties coordinated to deliver the steel structure smoothly.

The market procurement cycle of ultra-thick plate and thick steel is generally long. The steel plate with a width greater than 40mm and the material of Q390 needs to be specially customized. This procurement cycle is difficult to meet the urgent needs of on-site construction. In order to solve this problem, the technical department actively communicated with the design unit in advance, made precise layout, and the business department organized all resources to facilitate the steel mill to deliver on time, laying the foundation for subsequent processing and installation.

During this period, due to the urgency of the task, there was also a shortage of welders in the processing plant, and the steel components could not be processed. The project department coordinated more than 20 welders from external units to go to the processing plant for support, which relieved the pressure on the processing plant and created conditions for the delivery of steel components on time.

Facing technical difficulties, overcoming difficulties and achieving great results.

The portal frame structure is the core area of the whole building, and it is also the highlight and difficulty of the building structure.

Because the 100mm super thick steel plate on the upper and lower flanges and the 2000×1000 super-large cross-section welding volume is very large, the maximum welding volume of the bending section uses 12 coils of welding wire for one welding joint, and it took two welders three days and two nights. All welding can be completed, and in order to prevent shrinkage cracks, it is necessary to preheat before welding and heat preservation after welding.