Steel Structure Warehouse

2024/5/3 12:56:51

No Pics.

Introduction

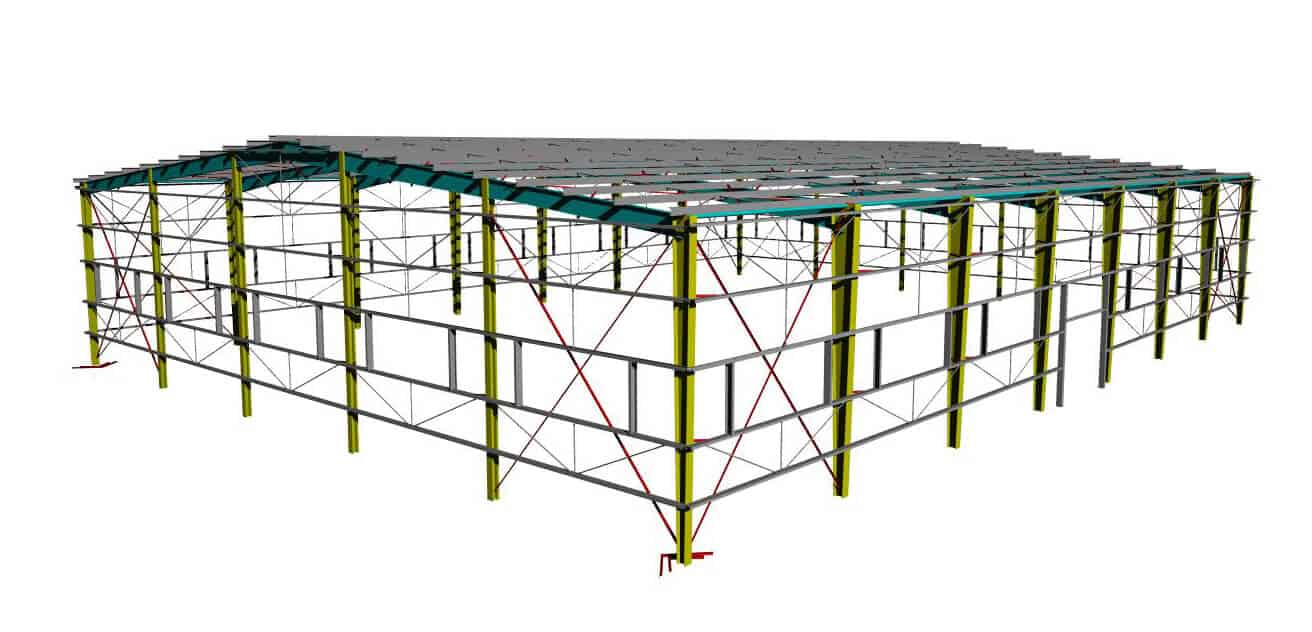

Steel Structure Warehouse

The main load-bearing component of a steel structure warehouse is a steel frame, including steel columns and roof beams. After fabrication at the factory, the main steel frames and secondary frames are transported to the site for installation. All components are prefabricated and can be installed directly without cutting and drilling on-site, saving installation time and labor costs.

The steel structure warehouse is a light steel building composed of steel columns, steel beams, supports, purlins, etc. All steel structure components are manufactured in the workshop and delivered to the project site, fast installation, green building, and saving workforce.

Prefab steel warehouses can meet a wide range of project needs-from commercial (car sheds, exhibition halls) to agriculture (metal warehouses, warehouse sheds) to industry (workshops, equipment warehouses).

2. Steel column, usually H-shaped steel (often connected with two C-shaped steel and angle steel)

3. Steel beams, generally H-shaped steel, (the span of the beam determines the height)

4. Roof purlins and wall enclosures: C-shaped steel and Z-shaped steel usually used.

5. The support typically uses round steel or L-shaped angle steel.

The steel structure warehouse is very durable. They are strong enough to withstand heavy snow, high winds, and strong earthquakes. The service life generally exceeds 50 years.

The walls and roof panels are hot-dips galvanized, or steel panels can also be coated with aluminum compounds to prevent rust and increase the life of the board, rust, and moisture. The roof insulated with glass wool or rock wool for heat insulation, sound insulation, and fire prevention.

The steel structure warehouse is cheap, and the construction period is fast, which is 1/3 of the ordinary construction period. The installation is simple; no professional technicians needed and save labor costs.

We designed the warehouse to maximize the use of internal space. There are free columns inside the warehouse, and the forklift can be used freely to improve warehouse utilization. The prefabricated steel structure warehouse is durable. It can withstand severe weather such as rain, snow, wind, and has excellent shock resistance. And the wall and roof cladding coated with aluminum compounds to prevent rust and extend service life.

For the second floor warehouse or the warehouse with mezzanine, the live load of the floor needs to calculate. Steel columns and platform beams should have sufficient strength to withstand the weight of stockpiled cargo.

Functional load-bearing capacity, material strength, thickness and the requirements of the force transmission method, the load-bearing capacity of metal roof panels, the section characteristics of the layout, etc. The construction method for daily maintenance of steel structure and extended service life.

Lighting design

The excellent lighting effect is conducive to energy conservation. Otherwise, indoor lighting needs to complete during the day and night, which undoubtedly increases energy consumption. The steel structure warehouse should pay attention to the lighting design, such as designing and arranging daylighting panels or installing lighting glass in a specific position on the metal roof, and at the same time doing waterproof work treatment to maximize the service life, good lighting effect, and natural lighting design.

2. Significantly reduce the use of concrete and bricks and tiles, and reduce the excavation of mountains and rocks around the city, which is beneficial to environmental protection;

3. When the service life of the building expires, less solid waste generated due to the demolition of the building, and the price of recycling scrap steel resources is high.

4. The prefabricated steel structure components can prefabricate in the factory. So it can reduce labor cost, speed up construction, shorten the construction period, guarantee the quality, and improve precast accuracy.

5. After being adequately prepared and heat-treated, the large and robust steel structure can improve the strength, toughness, and safety.

6. The calculation structure is accurate. The steel structure has uniform power and uniform steel strength, which is inferior to other materials.

The main load-bearing component of a steel structure warehouse is a steel frame, including steel columns and roof beams. After fabrication at the factory, the main steel frames and secondary frames are transported to the site for installation. All components are prefabricated and can be installed directly without cutting and drilling on-site, saving installation time and labor costs.

The steel structure warehouse is a light steel building composed of steel columns, steel beams, supports, purlins, etc. All steel structure components are manufactured in the workshop and delivered to the project site, fast installation, green building, and saving workforce.

Prefab steel warehouses can meet a wide range of project needs-from commercial (car sheds, exhibition halls) to agriculture (metal warehouses, warehouse sheds) to industry (workshops, equipment warehouses).

Steel Structure Warehouse

The steel structure warehouse mainly includes the following parts:

2. Steel column, usually H-shaped steel (often connected with two C-shaped steel and angle steel)

3. Steel beams, generally H-shaped steel, (the span of the beam determines the height)

4. Roof purlins and wall enclosures: C-shaped steel and Z-shaped steel usually used.

5. The support typically uses round steel or L-shaped angle steel.

The steel structure warehouse is very durable. They are strong enough to withstand heavy snow, high winds, and strong earthquakes. The service life generally exceeds 50 years.

The walls and roof panels are hot-dips galvanized, or steel panels can also be coated with aluminum compounds to prevent rust and increase the life of the board, rust, and moisture. The roof insulated with glass wool or rock wool for heat insulation, sound insulation, and fire prevention.

The steel structure warehouse is cheap, and the construction period is fast, which is 1/3 of the ordinary construction period. The installation is simple; no professional technicians needed and save labor costs.

steel structure warehouse

Description of Steel Structure Warehouse

We designed the warehouse to maximize the use of internal space. There are free columns inside the warehouse, and the forklift can be used freely to improve warehouse utilization. The prefabricated steel structure warehouse is durable. It can withstand severe weather such as rain, snow, wind, and has excellent shock resistance. And the wall and roof cladding coated with aluminum compounds to prevent rust and extend service life.

Steel Structure Warehouse

The Design

Load-bearing design

For the second floor warehouse or the warehouse with mezzanine, the live load of the floor needs to calculate. Steel columns and platform beams should have sufficient strength to withstand the weight of stockpiled cargo.

Functional load-bearing capacity, material strength, thickness and the requirements of the force transmission method, the load-bearing capacity of metal roof panels, the section characteristics of the layout, etc. The construction method for daily maintenance of steel structure and extended service life.

Lighting design

The excellent lighting effect is conducive to energy conservation. Otherwise, indoor lighting needs to complete during the day and night, which undoubtedly increases energy consumption. The steel structure warehouse should pay attention to the lighting design, such as designing and arranging daylighting panels or installing lighting glass in a specific position on the metal roof, and at the same time doing waterproof work treatment to maximize the service life, good lighting effect, and natural lighting design.

The Advantage

2. Significantly reduce the use of concrete and bricks and tiles, and reduce the excavation of mountains and rocks around the city, which is beneficial to environmental protection;

3. When the service life of the building expires, less solid waste generated due to the demolition of the building, and the price of recycling scrap steel resources is high.

4. The prefabricated steel structure components can prefabricate in the factory. So it can reduce labor cost, speed up construction, shorten the construction period, guarantee the quality, and improve precast accuracy.

5. After being adequately prepared and heat-treated, the large and robust steel structure can improve the strength, toughness, and safety.

6. The calculation structure is accurate. The steel structure has uniform power and uniform steel strength, which is inferior to other materials.