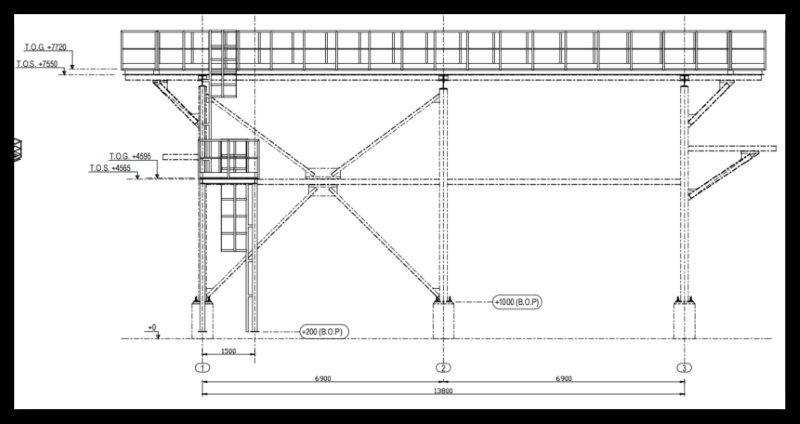

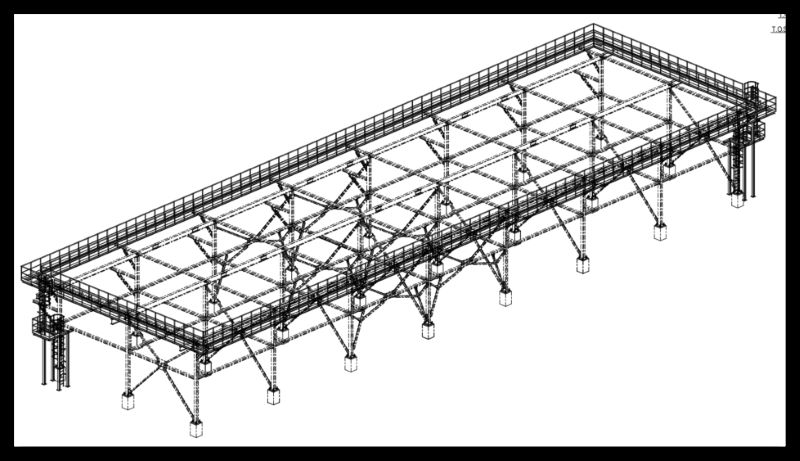

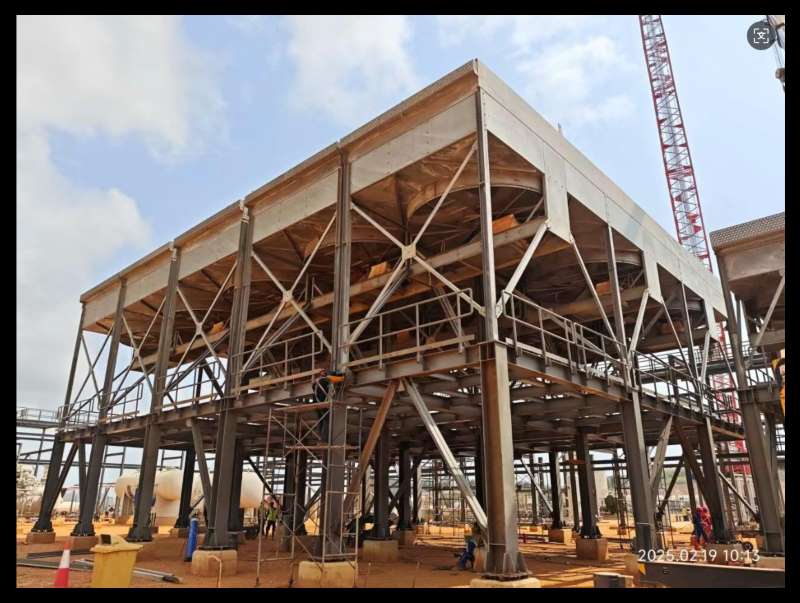

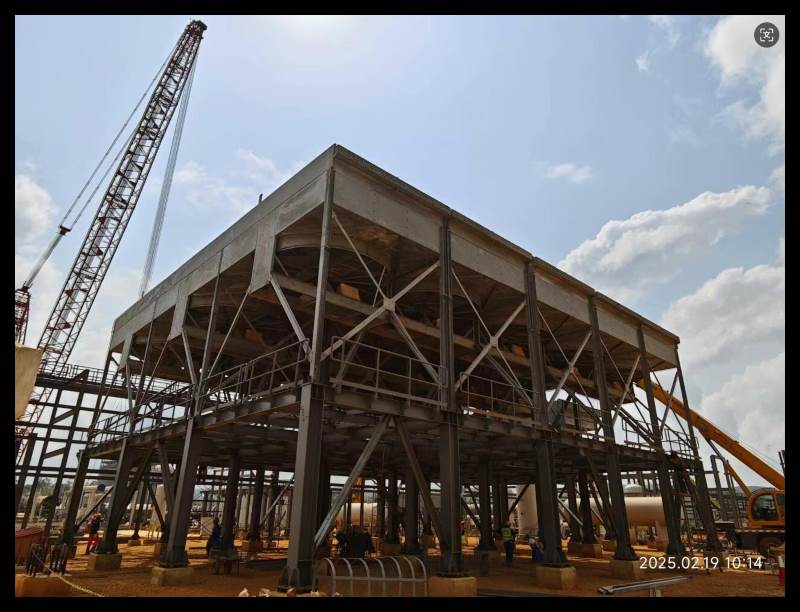

Project Name: Lower Structure ACC Air Coolers,GEX300-United Downs Deep Geothermal Project, Including Ladders, walkways,SS316L Bolts/Nuts/washers;

- welding acc. EN 15614

- welds quality acc. EN/ISO 5817 - C

- welds inspection acc. - EN17637

- all steel parts were hot dip galvanized according EN/ISO 1461

( suitable holes for zinc draining on hollow sections opened in workshop)

- handrails and ladder cages without HDG protection. Yellow safety color coating with painting cycle suitable for C4 corrosivity ambient according to ISO 12944 as agreed.

- Material certificates for plates/angles according to EN 10204 3.1/2.2 as agreed

- All production strictly carried out in accordance with

(1) Document List (2) Packing List, (3) Fabrication Plan, (4) Manufacturing Data Book(MDB), (5) Inspection Data Book, (6)ACC structures, (7)O&M Manual, (8) Painting/HDG Procedure/Certificate, (9) Packing Procedure, (10) Material Certificates, (11) ACC structure shop drawings (12) ACC structure Tekla Model

Project Overview:

1. Technical Specifications & Standards

Welding:

Procedures qualified per EN 15614 (ensures weld integrity).

Weld quality class EN/ISO 5817 - C (moderate quality for non-critical static loads).

Inspection via EN 17637 (visual weld examination).

Corrosion Protection:

Hot-dip galvanizing (HDG) per EN/ISO 1461 for steel parts, with zinc-draining holes in hollow sections (prevents trapped moisture).

Handrails/ladder cages: Painted with yellow safety coating for visibility, rated for C4 corrosivity (e.g., coastal/industrial environments) under ISO 12944.

Material Certification: Plates/angles certified to EN 10204 3.1/2.2 (traceability of material properties).

2. Fabrication & Quality Assurance

Fabrication Plan, Manufacturing/Inspection Data Books (MDB/IDB), Tekla Model (3D structural design).

Painting/HDG procedures, packing lists, and O&M manuals.

Documentation: Ensures traceability, e.g., material certificates validate steel quality; MDB records production steps.

3. Key Design Considerations

Material Selection:

SS316L bolts/nuts: High corrosion resistance for harsh geothermal environments.

HDG vs. Paint: HDG for structural longevity, paint for non-galvanized safety components.

Tekla Model: Ensures precision in shop drawings and clash detection during assembly.

4. Challenges & Mitigation

C4 Coating Durability: Confirm paint thickness/cycles meet ISO 12944 for salt-rich or humid environments.

Documentation Gaps: Audit MDB/IDB to ensure all inspections (e.g., weld checks) are recorded.

5. Stakeholder Implications

Client/Operator: Relies on O&M manuals for maintenance, especially for HDG/painted components.

Inspectors: Focus on weld quality (EN 5817-C) and HDG adherence (EN 1461).

Conclusion: This project emphasizes rigorous adherence to European standards, corrosion management for geothermal conditions, and robust documentation. Success hinges on coordination between fabrication (via Tekla), quality checks, and clear handover of operational guidelines.

Why ZHM Huawu Metal Lower Steel Structure Frames ACC Air Coolers?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Lower Steel Structure Frames ACC Air Coolers? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com